ISCOR корыч рельс/Корыч рельс/Тимер юл рельсы/Җылылык белән эшкәртелгән рельс

юл материалытимер юл транспортында поездларның авырлыгын күтәрә торган мөһим компонент, шулай ук поездлар хәрәкәте өчен инфраструктура булып тора. Ул югары ныклыклы корычтан ясалган, яхшы ныклыкка һәм тузуга чыдам, зур басымга һәм бәрелүгә чыдам.

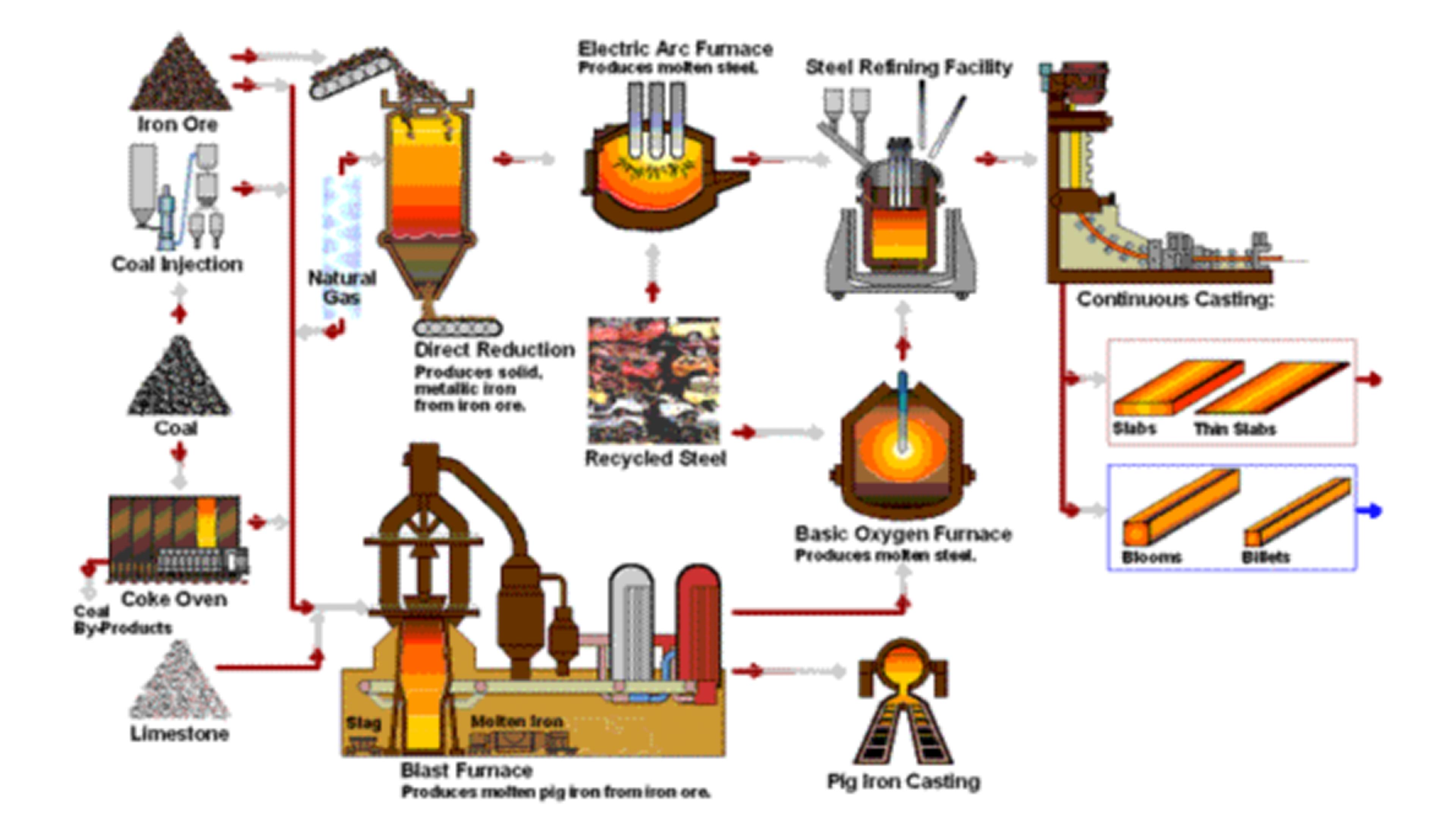

ПРОДУКТ ҖИТЕШТЕРҮ ПРОЦЕСЫ

Технология һәм төзелеш процессы

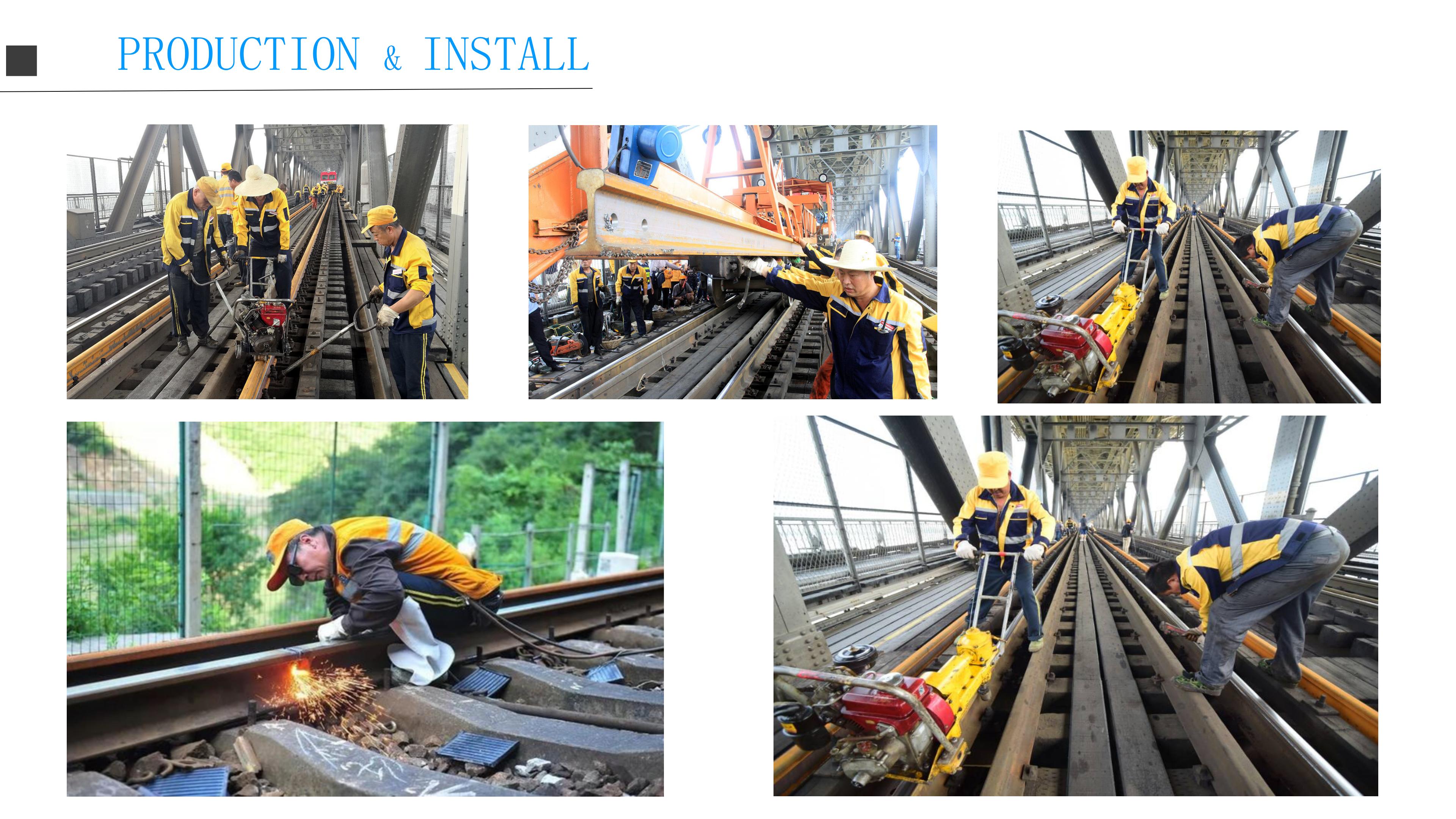

Төзелеш процессыsтимер рельсЮллар төгәл инженерияне һәм төрле факторларны җентекләп исәпкә алуны үз эченә ала. Ул юлның планын проектлаудан башлана, максатчан кулланылышны, поездларның тизлеген һәм җир рельефын исәпкә алып. Проект тәмамланганнан соң, төзелеш процессы түбәндәге төп адымнар белән башлана:

1. Казу эшләре һәм нигез: Төзелеш бригадасы җирне әзерли, территорияне казып һәм поездлар китергән авырлыкны һәм көчәнешне күтәрү өчен ныклы нигез булдыра.

2. Балласт урнаштыру: Әзерләнгән өслеккә балласт дип аталган вакланган таш катламы җәелә. Бу амортизацияләүче катлам булып хезмәт итә, тотрыклылык тәэмин итә һәм йөкне тигез бүлүгә ярдәм итә.

3. Бәйләүләр һәм беркетү: Аннары агач яки бетон бәйләүләр балласт өстенә урнаштырыла, рамка сыман конструкцияне кабатлый. Бу бәйләүләр корыч тимер юл рельслары өчен ныклы нигез булып тора. Алар махсус чәнечкеләр яки клиплар ярдәмендә беркетелә, шуның белән аларның ныклы урнашуын тәэмин итә.

4. Рельс урнаштыру: 10 м корыч тимер юл рельслары, еш кына стандарт рельслар дип атала, шпилькалар өстенә җентекләп урнаштырылган. Югары сыйфатлы корычтан эшләнгән бу рельслар гаҗәеп ныклыкка һәм чыдамлыкка ия.

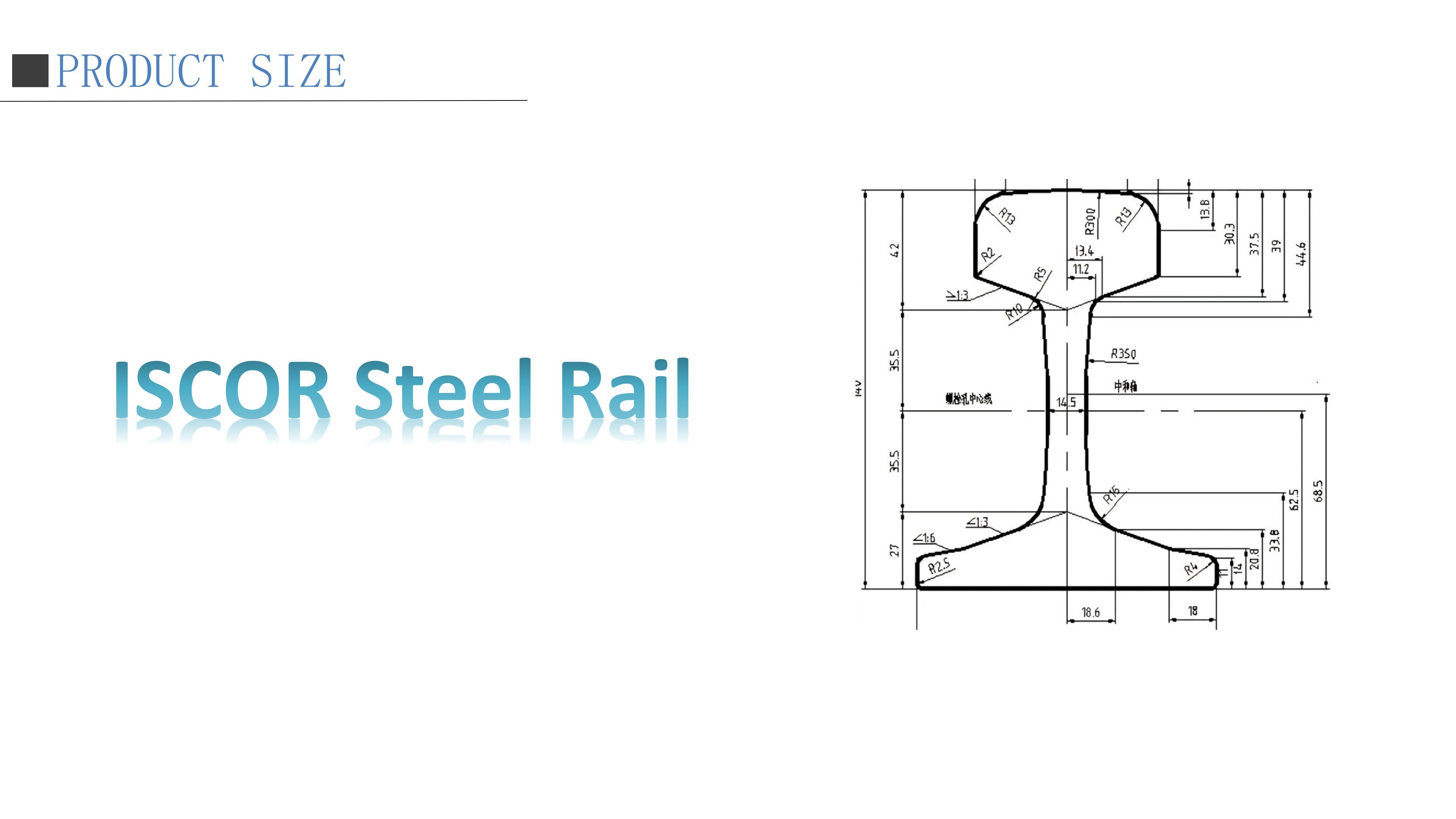

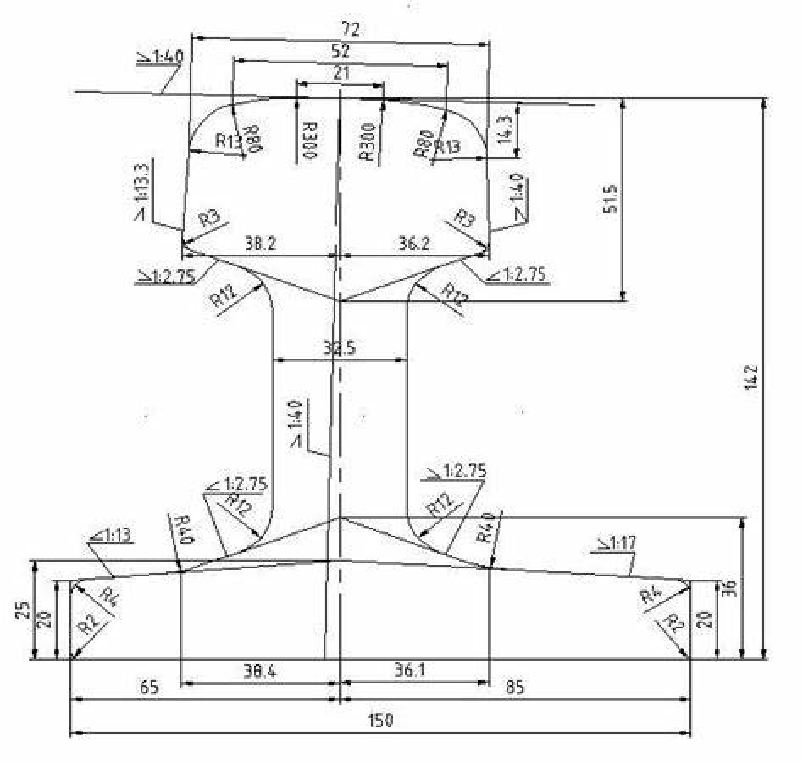

ПРОДУКТ ЗУРЛЫГЫ

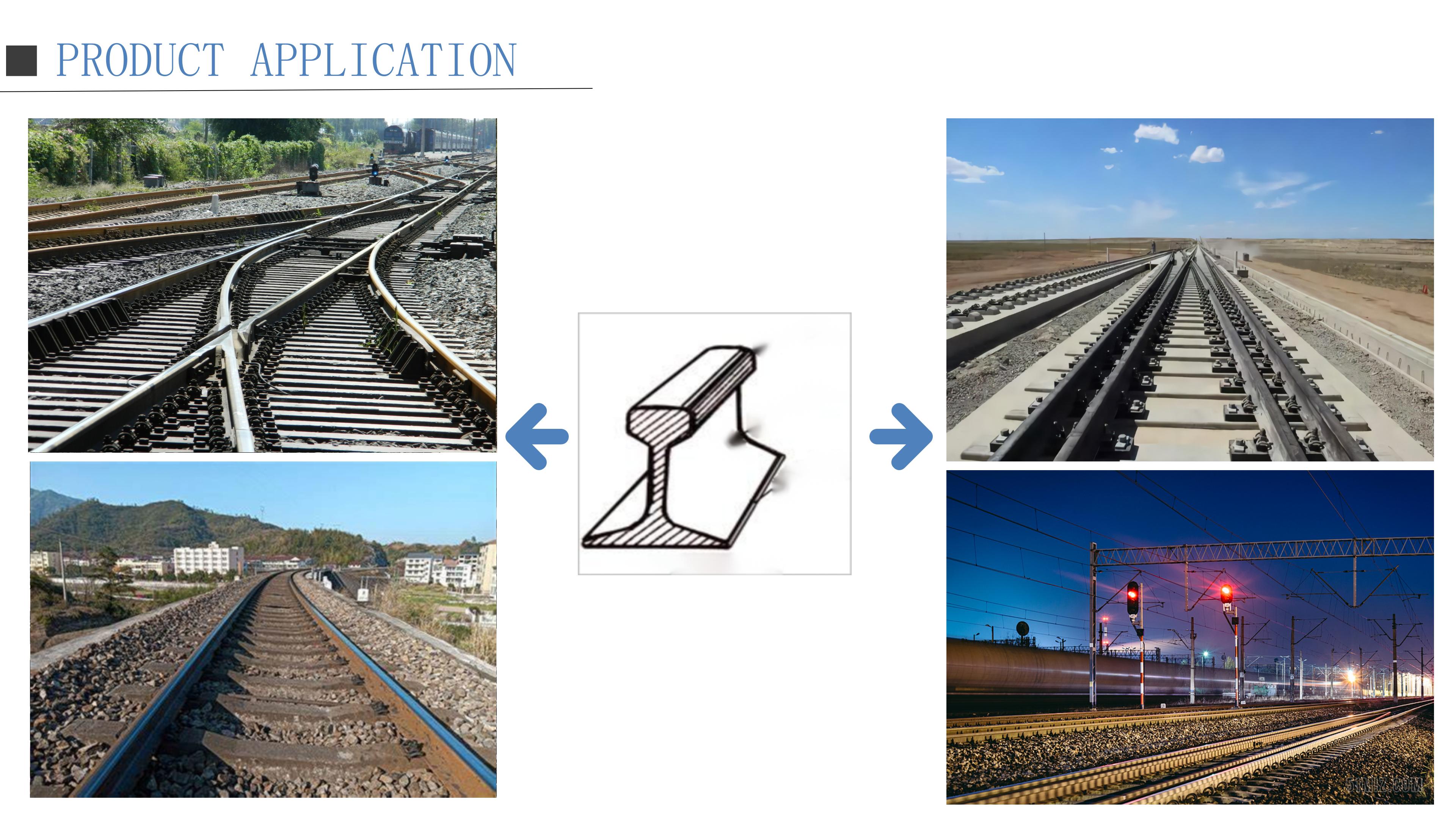

(1) Поездның авырлыгын тотып торыгыз:тимер юл корычыпоездлар йөрү өчен инфраструктура булып торалар һәм поездның һәм аның йөкләренең авырлыгын күтәрә алалар.

(2) Поездны хәрәкәт юнәлешендә юнәлтегез: Тимер юлда берничә тоташтырылган корыч рельс урнаштырылган. Алар поезд хәрәкәт итә торган юлны тәшкил итә һәм поездны билгеле бер юнәлештә хәрәкәт итәргә юнәлтә ала.

(3) Басымны тарату: Поезд үткәндә, рельслар авырлыкны җиргә тигез бүлә ала, бу деформациядән яки җиргә артык басым аркасында килеп чыккан зыяннан сакланырга ярдәм итә.

| ISCOR стандартлы корыч рельс | |||||||

| модель | зурлык (мм) | матдә | материал сыйфаты | озынлык | |||

| баш киңлеге | биеклек | нигез тактасы | бил тирәнлеге | (кг/м3) | (м) | ||

| А(мм | Б(мм) | К(мм) | Д(мм) | ||||

| 15 кг | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22 кг | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30 кг | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40 кг | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48 кг | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57 кг | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

Көньяк Африка тимер юллары:

Спецификацияләр: 15 кг, 22 кг, 30 кг, 40 кг, 48 кг, 57 кг

Стандарт: ISCOR

Озынлыгы: 9-25 м

ӨСТЕНЛЕК

2008 елда, почмакларында авыш тишекләре булган дүрт роликлы универсаль тәгәрмәч CCS500 универсалында сыналды.тимер юл рельсларытегермән. Сынау җитештерү планында гамәлдәге универсаль тупас эшкәртү һәм кырый прокатлау үткәргечләре кулланылган, һәм әзер үткәргечне өч роликтан дүрткә кадәр генә үзгәрткәннәр. Ролик, 8 сәгать дәвамында өзлексез прокатлау, 1000 тонна 60 кг/м рельс җитештерә.

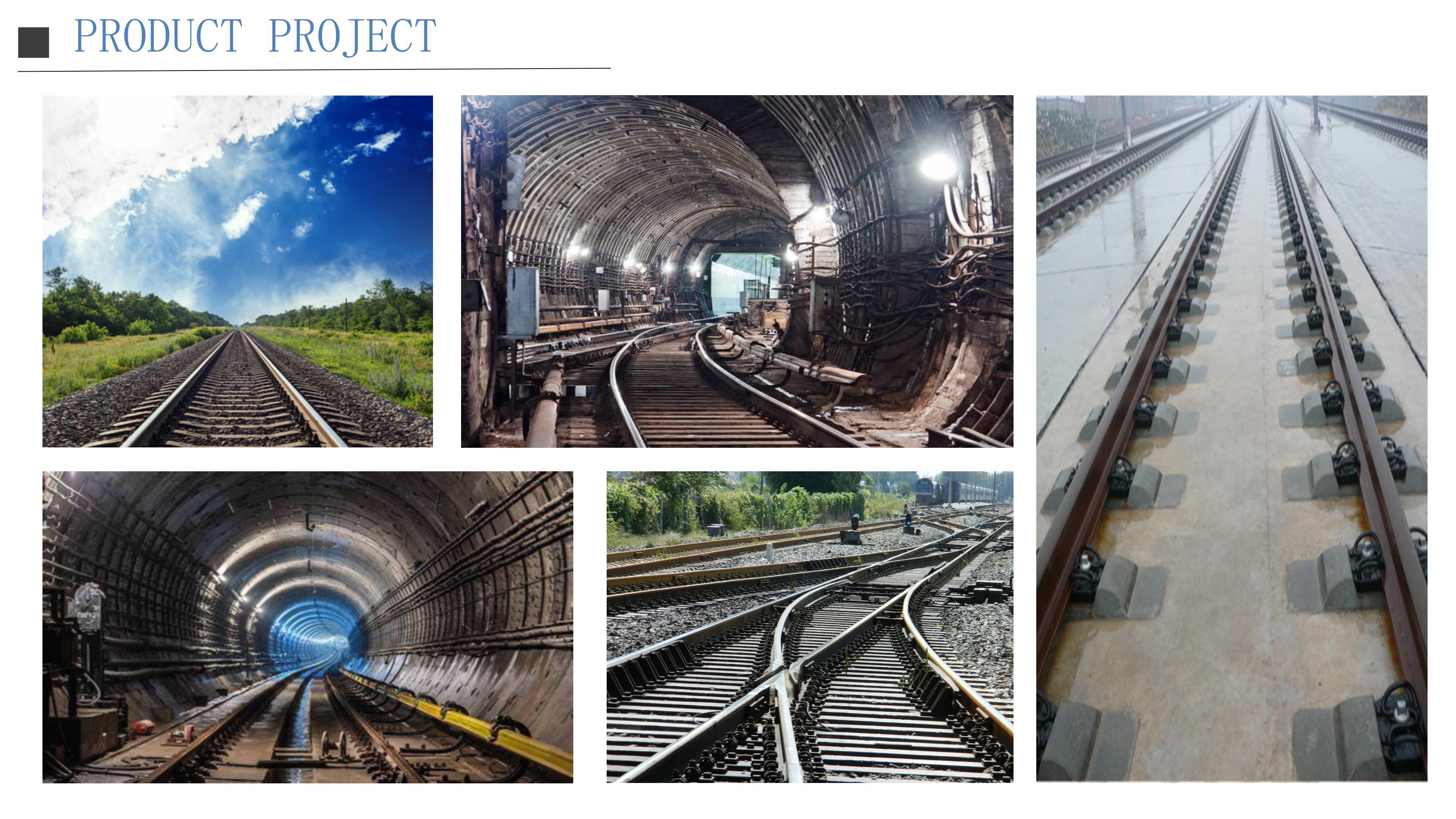

ПРОЕКТ

Корыч тимер юл транспорты системасында алыштыргысыз инфраструктура буларак, рельслар мөһим роль уйный. Ул поездның авырлыгын күтәрә, поезд юнәлешен күрсәтә, басымны тарата, ышкылуны киметә һәм поездның куркынычсызлыгын тәэмин итә ала. Рельсларны төрле стандартлар буенча күп төрләргә бүлергә мөмкин, һәр төрнең үз кулланылышы һәм өстенлекләре бар.

Кушымта

алыштыргысыз инфраструктура буларактимер юл рельсытранспорт системасында рельслар мөһим роль уйный. Ул поездның авырлыгын күтәрә, поезд юнәлешен күрсәтә, басымны тарата, ышкылуны киметә һәм поездның куркынычсызлыгын тәэмин итә ала. Рельсларны төрле стандартлар буенча күп төрләргә бүлергә мөмкин, һәр төрнең үз кулланылышы һәм өстенлекләре бар.

ТӨРҮ ҺӘМ ҖИБӘРҮ

1. Куркынычсызлыкны саклау чаралары

1. Куркынычсызлык каскалары, куркынычсызлык аяк киемнәре һәм перчаткалар кебек куркынычсызлык саклагыч чараларын киегез.

2. Әгәр сезгә биек биеклекләрдә яки тирән чокырларда кебек куркыныч урыннарда эшләргә туры килсә, сез куркынычсызлык каешларын һәм куркынычсызлык арканнарын кияргә тиеш.

3. Тимер юл транспортының авырлыгына, зурлыгына һәм авырлык үзәгенә игътибар итегез, артык йөкләү, чикләрне узу һәм кызыл светофорга чыгу кебек куркыныч гамәлләрне катгый тыегыз.

4. Эш урыны чиста, юл өслеге тигез, ә урнаштырылган җиһазлар нык һәм ышанычлы булырга тиеш.

5. Рельсларны ташыганда, кул белән ташудан саклану өчен, механикалаштырылган ташу коралларын мөмкин кадәр күбрәк кулланырга кирәк.

2. Җиһазлар сайлау

1. Эшкәртү бурычларының ихтыяҗларына туры китереп, тиешле күтәрү җиһазларын, мәсәлән, краннарны, краннарны һ.б. сайлагыз. Җиһазларның номиналь йөк күтәрүчәнлегенә игътибар итегез һәм күтәрү биеклеге һәм асылмалы нокталар кебек параметрларны билгеләгез.

2. Тимер юл транспортында төрле җиһазлар һәм ысуллар кулланыла ала, мәсәлән, арбалар, краннар, погрузчиклар яки кул белән тарту. Тиешле җиһазлар һәм ысуллар сайлау эш нәтиҗәлелеген арттырырга һәм хезмәт интенсивлыгын киметергә мөмкин.

3. Операция күнекмәләре

1. Рельсларны күчерү алдыннан, эш урынын чистартыгыз. Юл өслегенең чиста, тигез, коры һәм чүп-чар, вак таш, чокырлар һәм башка чүп-чардан азат булуына инаныгыз.

2. Рельсларны ташу алдыннан, башта күтәрү җиһазларының һәм транспорт коралларының эш торышын һәм куркынычсызлык күрсәткечләрен тикшерергә кирәк. Тәгәрмәчләрнең, тормозларның, элгечләрнең, күтәрү арканнарының, элгечләрнең һәм башка компонентларның өслек торышын һәм эш динамикасын тикшерегез.

3. Рельсларны ташыганда, мөмкин кадәр бәрелүләрдән һәм бәрелүләрдән сакланырга кирәк. Аларны шома күтәрергә, шома ташырга һәм шома куярга кирәк.

4. Рельсларны ташу процессында тирә-юнь мохиткә һәм киртәләргә игътибарлы булыгыз, куркынычсыз эшләүне тәэмин итү өчен вакытында куркынычсызлык чараларын һәм булдырмау чараларын күрегез.

5. Рельслар озынлыгына һәм авырлыгына карап йөкләнергә һәм эшкәртелергә тиеш. Артык озын һәм артык авыр рельслар өчен аларны кисәкләргә бүлеп ташырга яки тиешле киңәйтү транспорт җиһазларын кулланырга кирәк.

6. Рельсларны ташу процессында, рельс өслегендә зыян яки тузу булмасын өчен, рельсларны коррозиягә каршы эшкәртүгә игътибар итегез.

Рельсларны урнаштырганда яки ташыганда игътибар итәргә кирәк булган әйберләр югарыда күрсәтелгән. Бу саклык чаралары ташу процессында һәлакәтләрне һәм куркынычларны нәтиҗәле рәвештә киметергә һәм ташуның куркынычсызлыгын һәм нәтиҗәлелеген тәэмин итәргә мөмкин.

КОМПАНИЯ КӨЧЕ

Кытайда эшләнгән, беренче класслы хезмәт күрсәтү, алдынгы сыйфат, дөньякүләм танылган

1. Масштаб эффекты: Безнең компания зур тәэмин итү чылбырына һәм зур корыч заводына ия, транспорт һәм сатып алуларда масштаб эффектларына ирешә, һәм җитештерү һәм хезмәт күрсәтүне берләштергән корыч компаниясенә әйләнә.

2. Продукция төрлелеге: Продукция төрлелеге, сез теләгән теләсә нинди корычны бездән сатып алырга мөмкин, нигездә, корыч конструкцияләр, корыч рельслар, корыч шпунт свайлар, фотоэлектрик кронштейннар, канал корыч, кремний корыч катушкалар һәм башка продуктлар белән шөгыльләнә, бу аны тагын да сыгылмалырак итә. Төрле ихтыяҗларны канәгатьләндерү өчен теләгән продукт төрен сайлагыз.

3. Тотрыклы тәэмин итү: Тотрыклырак җитештерү линиясе һәм тәэмин итү чылбыры булу ышанычлырак тәэмин итүне тәэмин итә ала. Бу, бигрәк тә, күп күләмдә корыч таләп итүче сатып алучылар өчен мөһим.

4. Бренд йогынтысы: Бренд йогынтысы югарырак һәм базар зуррак

5. Хезмәт күрсәтү: Заказлаштыру, транспорт һәм җитештерүне берләштергән зур корыч компаниясе

6. Бәя көндәшлеге: акылга сыярлык бәя

*Электрон почтаны түбәндәге адрес буенча җибәрегез[email protected]проектларыгыз өчен бәя алу өчен

КЛИЕНТЛАР КИЛҮЕ

еш бирелә торган сораулар

1. Сездән ничек бәя алырга мөмкин?

Сез безгә хәбәр калдыра аласыз, һәм без һәр хәбәргә вакытында җавап бирербез.

2. Сез товарларны вакытында китерәсезме?

Әйе, без иң югары сыйфатлы продуктлар һәм вакытында китерүне вәгъдә итәбез. Намуслылык - безнең компаниянең принцибы.

3. Заказ бирү алдыннан үрнәкләр ала аламмы?

Әйе, әлбәттә. Гадәттә безнең үрнәкләр бушлай, без сезнең үрнәкләрегез яки техник рәсемнәрегез буенча җитештерә алабыз.

4. Түләү шартлары нинди?

Гадәттәге түләү вакыты - 30% алдан түләү, ә калганы B/L. EXW, FOB, CFR, CIF.

5. Сез өченче як тикшерүен кабул итәсезме?

Әйе, без, әлбәттә, кабул итәбез.

6. Сезнең компаниягә ничек ышанабыз?

Без күп еллар дәвамында корыч бизнесында алтын белән тәэмин итүче буларак махсуслашабыз, штаб-фатирыбыз Тяньцзинь провинциясендә урнашкан, теләсә нинди ысул белән тикшерергә рәхим итегез.